I remember walking onto a high-pressure refinery turnaround project where the Site Manager introduced me to the team as "the guy here to stop the work." It was a classic misconception; the room went silent, and I could feel the tension immediately shift. I had to step in and correct the narrative right then and there, explaining that my job wasn't to stop the work, but to ensure they all went home to their families so they could come back and finish the work tomorrow. That moment defines the core struggle and reality of a Health and Safety Practitioner: we are often misunderstood as blockers when, in reality, we are the ultimate enablers of sustainable operations.

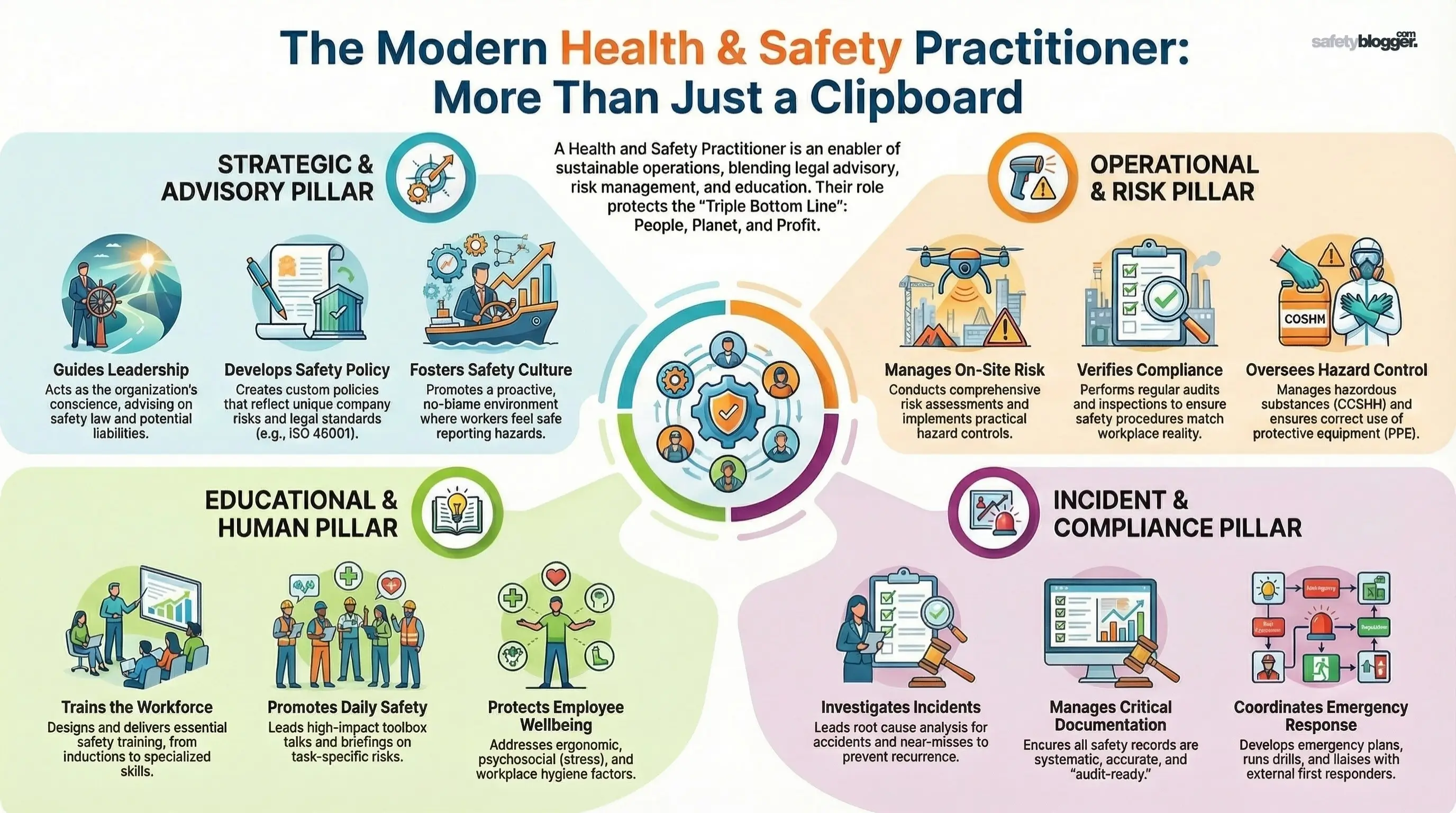

The scope of a Health and Safety Practitioner goes far beyond holding a clipboard and checking boxes; it is a complex blend of legal advisory, engineering controls, psychology, and crisis management. In this article, I will break down the 15 critical roles and responsibilities that define this profession, moving from strategic governance to the gritty reality of field operations. Whether you are an aspiring safety officer or an employer trying to understand the value of this role, understanding these duties is essential for building a safety culture that survives beyond the audit.

The Strategic & Advisory Pillar

A safety practitioner operates as the conscience of the organization, guiding leadership through the regulatory maze to ensure top-level commitment. This is where we bridge the gap between business goals and ethical obligations.

1. Developing and Updating Safety Policies

The foundation of any safety management system is the Health & Safety Policy Statement. In my experience auditing major multinationals, I often see policies that are copy-pasted generic templates. My duties here include:

Drafting policies that specifically reflect the unique risks of the organization rather than using generic text.

Ensuring total alignment with local legislation (e.g., OSHA, HSE UK) and international standards like ISO 45001.

Reviewing policies annually or immediately following significant operational changes to maintain legal defensibility.

Distributing the policy effectively so every worker, from the CEO to the cleaner, understands their specific obligations.

2. Acting as a Competent Advisory Resource

Directors and operations managers are experts in production, not necessarily in safety law. I serve as their primary resource for interpreting complex health and safety regulations. My responsibilities include:

Translating complex legal jargon into actionable, plain-English business steps for management.

Advising on the legal implications of new machinery purchases or process changes.

Providing guidance on regulatory requirements when the company expands into new jurisdictions or sectors.

Warning leadership of potential criminal and civil liabilities regarding specific safety decisions.

3. Fostering a Proactive Safety Culture

Moving an organization from "reactive" (fixing things after an accident) to "proactive" (preventing them before they happen) is perhaps my most difficult task. To achieve this, I am responsible for:

Promoting a "no-blame" culture where workers feel safe reporting hazards without fear of reprisal.

Engaging directly with the workforce to build trust and demonstrate that safety is a core value.

Organizing safety committees that give workers a voice in decision-making processes.

Challenging unsafe behaviors immediately and constructively to set the standard on-site.

Auditor Insight: A policy on the wall means nothing if the culture on the floor ignores it. During audits, I measure culture by interviewing the newest employee, not the CEO.

The Operational & Risk Pillar

This is where the rubber meets the road. These responsibilities involve the day-to-day "hands-on" technical work that directly protects workers from harm.

4. Conducting Comprehensive Risk Assessments

I am responsible for identifying physical, chemical, biological, and ergonomic hazards across the worksite. This isn't just about spotting a trip hazard; it involves a systematic evaluation.

Identifying all potential hazards associated with work activities and the environment.

Evaluating the likelihood and severity of harm to calculate a risk score.

Implementing control measures based on the Hierarchy of Controls (prioritizing Elimination over PPE).

Reviewing risk assessments regularly to ensure controls remain effective over time.

5. Performing Regular Safety Audits and Inspections

I conduct scheduled site walk-throughs to verify compliance with the Safety Management System (SMS). While inspections are quick checks, audits are deep dives. My duties are:

Conducting daily or weekly physical inspections to identify immediate hazards like blocked exits or spills.

Performing deep-dive system audits to verify that procedures match reality.

Generating non-conformance reports (NCRs) for any deviations found during checks.

Verifying that corrective actions from previous audits have been effectively closed out.

6. Management of Hazardous Substances (COSHH)

Managing chemical safety is critical, particularly in manufacturing and oil and gas. I must ensure the organization respects chemical safety laws.

maintaining an up-to-date hazardous substance register for all chemicals on site.

Ensuring current Safety Data Sheets (SDS) are physically accessible to all relevant workers.

Verifying that all containers are properly labeled with correct hazard symbols.

Enforcing segregation rules in storage areas to prevent dangerous chemical reactions.

7. Overseeing Personal Protective Equipment (PPE) Compliance

My role is not just to hand out hard hats; it is to select the correct PPE for specific tasks based on risk assessments.

Selecting appropriate PPE that meets specific safety standards (e.g., ANSI, EN).

Organizing fit-testing sessions, particularly for respiratory protection (RPE).

Training staff on how to inspect, clean, and store their gear properly.

Monitoring inventory levels to ensure critical safety gear is never out of stock.

The Educational & Human Pillar

You can have the best systems in the world, but if the people aren't engaged or competent, the systems will fail. This pillar focuses on communication and well-being.

8. Designing and Delivering Safety Training

I design and facilitate training programs ensuring everyone is competent to do their job safely.

Conducting comprehensive safety inductions for all new hires and contractors.

Identifying training gaps (Training Needs Analysis) across the workforce.

Delivering specialized training sessions (e.g., Lockout/Tagout, Work at Height, Fire Warden).

Maintaining a centralized training matrix to track expirations and refresher due dates.

9. Leading Toolbox Talks and Safety Briefings

These are short, high-impact meetings held daily or weekly directly on the site. My role involves:

Translating technical safety data into simple, actionable language for the crew.

Briefing teams on specific risks relevant to the day's tasks (e.g., high wind conditions for cranes).

Encouraging two-way communication where workers can raise concerns before work starts.

Documenting attendance to prove that information was communicated.

10. Managing Employee Health and Wellbeing

Modern safety goes beyond physical injury; it encompasses health and hygiene. I address these by:

Conducting ergonomic assessments for office and manual handling tasks (DSE Assessments).

Monitoring workplace hygiene factors like noise levels, dust, and lighting.

Implementing programs to manage psychosocial risks and work-related stress.

Coordinating health surveillance for workers exposed to specific hazards (e.g., lead or silica).

The Incident & Compliance Pillar

When prevention fails, my role shifts to forensic investigation and regulatory liaison to prevent recurrence and manage legal fallout.

11. Incident Investigation and Root Cause Analysis

When an accident or "near-miss" occurs, I lead the investigation to find the system failure, not the scapegoat.

Securing the scene of the incident to preserve evidence.

Interviewing witnesses and gathering factual data immediately.

Applying root cause analysis techniques like "The 5 Whys" or "Fishbone Diagrams."

Producing a formal investigation report with actionable recommendations to prevent recurrence.

12. Maintaining Accurate Safety Documentation

In the world of HSE, the saying goes: "If it isn't written down, it didn't happen." I ensure documentation is "audit-ready."

Keeping the statutory accident book and medical logs up to date.

Filing all risk assessments, permits, and training records systematically.

Ensuring version control so that obsolete documents are removed from circulation.

Preparing documentation packages for external auditors or government inspectors.

13. Regulatory Reporting (RIDDOR/National Equivalents)

I fulfill the legal duty to report specific events to the government to avoid fines and legal action.

Identifying which incidents meet the criteria for statutory reporting (e.g., major fractures, fatalities).

Submitting reports to authorities (like OSHA or HSE) within strict legal timeframes.

Serving as the primary point of contact for any follow-up government inquiries.

Archiving confirmation of reports for legal defense purposes.

14. Coordinating Emergency Preparedness

I ensure that if the worst happens, the organization is ready to respond instantly.

Developing and maintaining site-specific emergency evacuation plans.

Scheduling and critiquing regular fire drills and evacuation exercises.

Liaising with external services (Fire, Police) to familiarize them with site hazards.

Inspects emergency equipment like AEDs, spill kits, and eye-wash stations regularly.

15. Contractor and Subcontractor Management

Outsourcing work doesn't mean outsourcing liability. I manage third-party risks by:

Vetting contractor safety records and insurance before they are hired.

Inducting contractor personnel on specific site rules and hazards.

Issuing Permits to Work for high-risk activities (e.g., Hot Work, Confined Space).

Monitoring contractor performance and removing unsafe workers from the site if necessary.

Pro Tip: Always treat contractors as high-risk. They don't know your site's "unwritten rules" or specific hazards. A robust permit-to-work system is your best defense here.

Conclusion

The 15 roles detailed above protect what we call the "Triple Bottom Line": People, Planet, and Profit. A skilled Health and Safety Practitioner does not just enforce rules; they facilitate a working environment where efficiency and safety coexist. We are the architects of a system that allows business to thrive without treating human capital as disposable.

As you step into or evaluate this role, remember that compliance is the floor, not the ceiling. Our ultimate responsibility is moral: ensuring that every single person under our care returns home in the same condition they arrived.

Comments

Loading...