I recall sitting across from a Managing Director in a tense post-incident investigation meeting after a severe crush injury at a manufacturing plant. He looked at the accident report, pale-faced, and asked, "How could we have prevented this? We gave him a helmet." It was a moment that underscored a fatal misunderstanding I see frequently: employers often believe safety stops at Personal Protective Equipment (PPE). I had to explain that his responsibility began long before that helmet was issued—it started with the machine guarding, the risk assessment, and the training that never happened.

That meeting wasn't unique; I have audited countless organizations where leadership viewed safety as a delegated task rather than a core executive function. This article outlines the 15 non-negotiable health and safety responsibilities every employer holds. Whether you are running a multinational construction firm or a local logistics hub, these duties form the bedrock of your legal compliance under OSHA or ISO 45001, and more importantly, they are the only barrier standing between your workforce and catastrophe.

1. Providing a Safe Place of Work

This is the foundational duty of care. In my experience auditing aging industrial facilities, I often find that "safe place" is interpreted too narrowly. It isn't just about keeping the floors dry; it covers the structural integrity of the building, proper ventilation, and lighting.

Structural Safety: Ensuring that buildings, gangways, and platforms are stable and capable of bearing required loads.

Housekeeping: Maintaining a clutter-free environment to prevent slips, trips, and falls—the most common cause of injury I encounter.

Environmental Control: Managing noise, temperature, and air quality to prevent long-term occupational diseases.

2. Conducting Rigorous Risk Assessments

I cannot count the number of times I’ve asked for a risk assessment and been handed a generic document downloaded from the internet. A risk assessment must be a living document that identifies hazards specific to your site operations.

Hazard Identification: Actively looking for potential sources of harm, from chemical exposure to working at heights.

Risk Evaluation: Determining the likelihood and severity of harm using a risk matrix.

Control Measures: Implementing the Hierarchy of Controls (Elimination, Substitution, Engineering, Admin, PPE) to mitigate identified risks.

3. Safe Plant and Equipment

Machinery failures are responsible for some of the most gruesome injuries I have investigated. Employers must ensure that all equipment, from heavy cranes to handheld drills, is fit for purpose and maintained.

Regular Maintenance: Establishing a preventative maintenance schedule rather than waiting for breakdowns.

Safety Guards: Ensuring interlocks and physical guards are in place and functioning to prevent contact with moving parts.

Pre-Use Inspections: Mandating that operators check their equipment before every shift.

4. Safe Systems of Work (SSoW)

Hardware is useless if the process is flawed. I often find that accidents happen not because a machine broke, but because the procedure for using it was ambiguous or dangerous. Employers must define safe methods for high-risk tasks.

Standard Operating Procedures (SOPs): Writing clear, step-by-step instructions for tasks.

Permit to Work: strictly enforcing permit systems for high-risk activities like confined space entry or hot work.

Lockout/Tagout (LOTO): Ensuring energy isolation procedures are documented and followed during maintenance.

5. Information, Instruction, and Training

Competency is a legal requirement, not a "nice to have." In many inquiries, I’ve found that the injured worker simply didn't know the safe way to perform the task. Employers must provide training relevant to the specific risks of the job.

Induction Training: Ensuring every new hire understands site-specific hazards before they start work.

Refresher Courses: Keeping skills up to date, especially for certifications like forklift driving or first aid.

Language Accessibility: Providing training in a language the workforce actually understands.

6. Supervision and Monitoring

You cannot just train workers and walk away. During site walkthroughs, I frequently spot unsafe behaviors that persist simply because supervision is lax. Employers must actively monitor the workplace to ensure procedures are being followed.

Active Supervision: Managers and supervisors must be present and observant, correcting unsafe acts immediately.

Safety Audits: Conducting regular internal inspections to catch non-conformance early.

Disciplinary Action: having a clear consequence management system for willful safety violations.

7. Provision of Adequate PPE

While PPE is the least effective control, it is often the last line of defense. As an employer, you must provide this free of charge. I have seen sites where workers taped up broken boots because they were afraid to ask for new ones—this is a leadership failure.

Selection: Choosing the correct PPE for the hazard (e.g., specific filter types for respirators).

Maintenance: Ensuring PPE is clean, stored correctly, and replaced when damaged.

Training: Teaching workers how to wear and adjust their gear properly.

Pro Tip: If you see a worker wearing PPE incorrectly, don't just correct them. Ask why. Often, the gear is uncomfortable, incompatible with other equipment, or simply the wrong size.

8. Emergency Preparedness and Response

When the alarm sounds, panic is your enemy. I have managed evacuation drills where half the workforce didn't know where the assembly point was. Employers must plan for the worst-case scenarios, including fires, spills, and medical emergencies.

Evacuation Plans: Clear, posted routes and assembly points.

Drills: Conducting full-scale emergency drills at least annually (or as per local regulation).

First Aid: Providing adequate first aid kits and trained personnel on every shift.

9. Consultation with Employees

Your workers know the risks better than anyone sitting in an office. ISO 45001 places huge emphasis on worker participation. Employers must legally consult with the workforce on matters affecting their health and safety.

Safety Committees: Forming groups comprising management and worker representatives to discuss safety issues.

Toolbox Talks: Daily briefings where workers can raise concerns before work starts.

Open Door Policy: creating a culture where reporting a hazard doesn't lead to retaliation.

10. Welfare Facilities

Safety isn't just about preventing injuries; it's about dignity and hygiene. I have shut down sites where the lack of potable water or sanitary toilets posed a severe health risk to the workforce.

Sanitation: Clean toilets and washing facilities with soap and water.

Drinking Water: Access to unlimited, clean drinking water, especially in hot environments.

Rest Areas: A place to eat and rest, away from hazardous work zones.

11. Reporting and Investigation of Incidents

If you don't report near-misses, you are waiting for a fatality. Employers are responsible for establishing a system where all incidents are reported, recorded, and investigated to prevent recurrence.

Reporting System: An easy, non-punitive way for workers to report accidents and near-misses.

Root Cause Analysis: Investigating why an incident happened, not just what happened.

Regulatory Reporting: Notifying authorities (like OSHA or HSE) of serious injuries or fatalities within statutory timeframes.

12. Health Surveillance

In industries like mining or petrochemicals, the harm isn't always immediate. Occupational diseases like silicosis or noise-induced hearing loss develop over years. Employers must monitor the health of workers exposed to specific hazards.

Audiometry: Hearing tests for those working in high-noise zones.

Respiratory Checks: Lung function tests for workers exposed to dust or fumes.

Records Management: Keeping confidential health records to track exposure over time.

13. Contractor Management

You cannot outsource your liability. If a contractor gets hurt on your site due to your negligence, you are responsible. I always advise clients to vet their contractors' safety records as rigorously as their pricing.

Prequalification: Checking the safety history and insurance of contractors before hiring.

Induction: Ensuring contractors follow the same safety rules as direct employees.

Oversight: Monitoring contractor work to ensure they aren't cutting corners.

14. Creating a Safety Policy

This is your statement of intent. It tells the world and your workforce where you stand. I look for this document first during an audit; if it's not signed by the current CEO or is dated five years ago, I know safety isn't a priority.

Clear Objectives: Stating the company's commitment to preventing injury and ill health.

Responsibilities: Defining who is responsible for what within the organization.

Communication: Displaying the policy prominently where all employees can read it.

15. Providing Adequate Resources

Finally, safety costs money, but accidents cost more. The "General Duty" implies that employers must allocate sufficient budget and time to manage safety effectively. Cutting the safety budget is a short-term gain that often leads to long-term ruin.

Financial Budget: Allocating funds for training, maintenance, and PPE.

Time: Allowing workers enough time to do the job safely without rushing.

Personnel: Hiring qualified safety professionals to advise and manage the system.

Summary of Critical Responsibilities

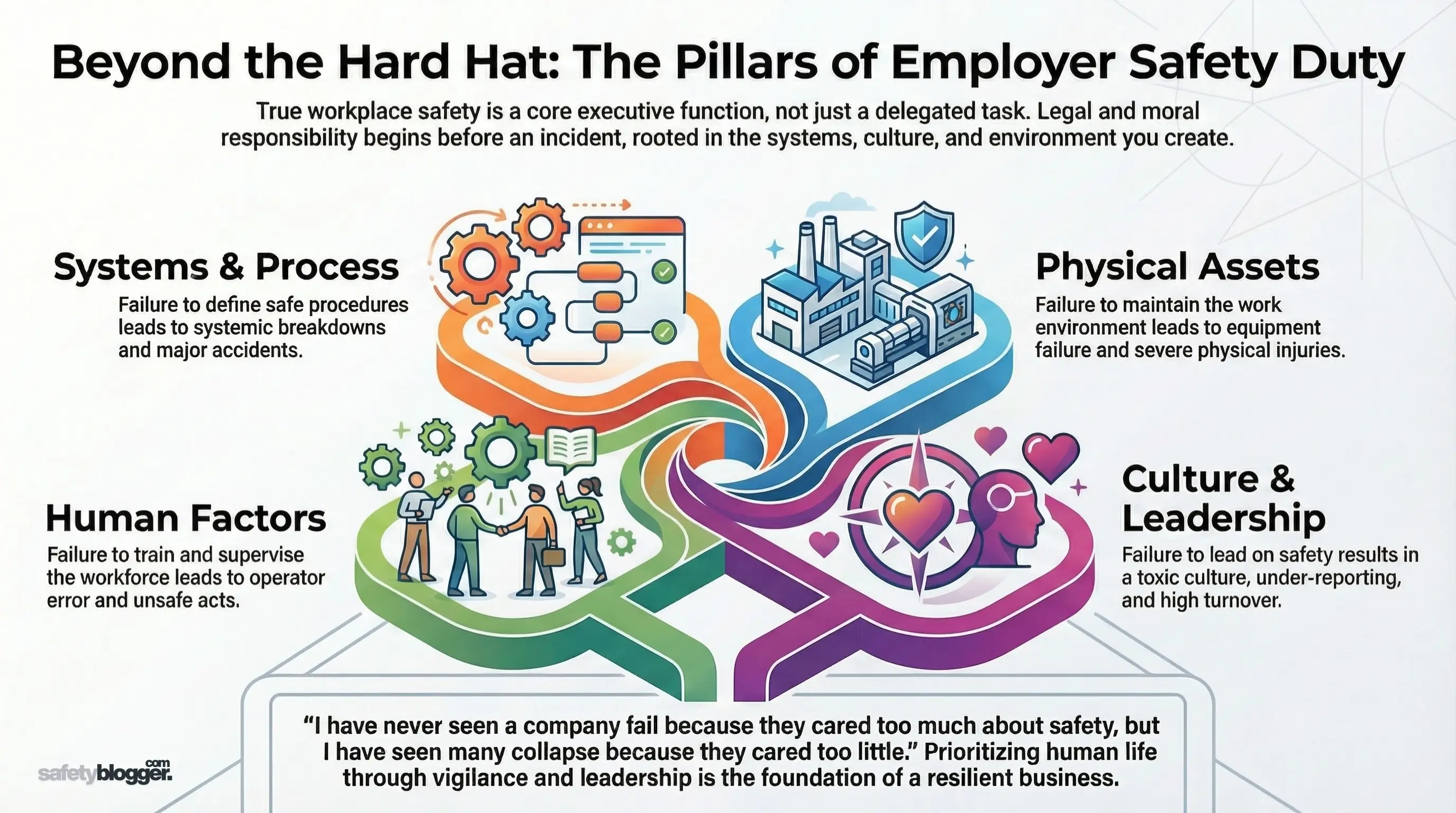

Responsibility Category | Key Action Item | Impact of Failure |

Physical Assets | Maintenance of plant & equipment | Mechanical failure, amputation, crush injuries |

Human Factors | Training & Competency | Operator error, unsafe acts, poor decisions |

Systems & Process | Risk Assessment & SSoW | Systemic failure, legal prosecution, major accidents |

Culture & Leadership | Consultation & Policy | Toxic culture, under-reporting, high turnover |

Conclusion

These 15 responsibilities are not merely a checklist for a regulatory inspector; they are the framework that keeps your people alive. In my decade of experience, I have never seen a company fail because they cared too much about safety, but I have seen many collapse because they cared too little.

Fulfilling these duties requires constant vigilance and genuine leadership. It is about moving beyond "paper safety" and ensuring that every decision, from the boardroom to the shop floor, prioritizes human life.

Comments

Loading...