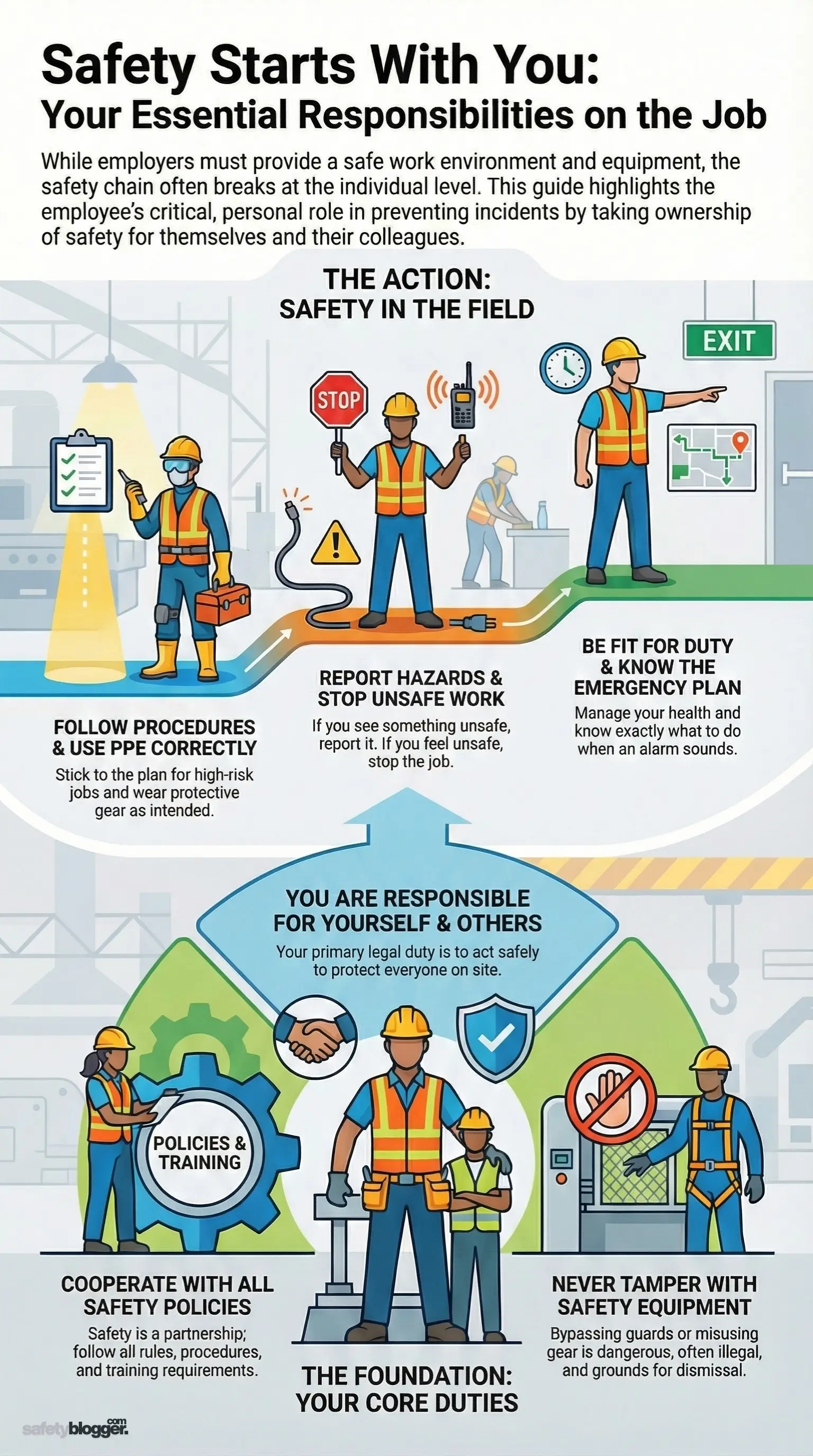

I was conducting a root cause analysis for a serious hand injury on a petrochemical expansion project when the injured pipefitter told me, "I just thought it would be quicker to bypass the guard." That single sentence highlighted a critical gap that I have seen on countless sites, from mining operations in Australia to high-rise construction in the Middle East. While employers have a massive burden to provide safe systems, equipment, and training, the safety chain often breaks down at the individual level. We can spend millions on engineering controls and ISO 45001 management systems, but if the person at the toolface doesn't accept their personal role in the safety ecosystem, incidents are inevitable.

This article outlines the 20 critical health and safety responsibilities that every employee holds, regardless of their rank or industry. This isn't just about ticking boxes for compliance or avoiding a reprimand; it is about the fundamental legal and moral "Duty of Care" you owe to yourself and the colleagues working beside you. Drawing from over a decade of field experience enforcing safety standards and investigating failures, I will break down exactly what is expected of you on the ground to ensure everyone goes home in the same condition they arrived.

Fundamental Legal & Ethical Duties

These first responsibilities form the foundation of your employment. In almost every jurisdiction—whether under OSHA in the US, the HSE in the UK, or local labor laws—these are non-negotiable statutory obligations.

1. Take Reasonable Care of Your Own Safety

Your primary responsibility is self-preservation within the boundaries of the rules. You must act in a way that does not put your life or health at risk.

Assess your state of mind: Never start a task if you are fatigued, stressed, or under the influence of substances that impair judgment.

Avoid shortcuts: Resist the urge to rush a job to meet a deadline if it compromises safety protocols.

Stay within your limits: Do not attempt tasks that require physical strength or agility beyond your current capability.

2. Take Reasonable Care of Others

You are your brother’s keeper. Your actions—or lack of action—must not endanger the people working around you, visitors, or the public.

Watch your surroundings: Be aware of where your colleagues are standing, especially when operating machinery or moving heavy loads.

Secure your work area: ensure that your tools and materials do not create trip hazards or falling object risks for others.

Communicate intent: clearly signal your intentions before starting equipment or energizing systems to warn those nearby.

3. Cooperate with the Employer

Safety is a partnership. When your employer implements a safety policy or procedure to comply with the law, you have a legal duty to cooperate with them.

Participate in initiatives: Engage actively in safety campaigns, toolbox talks, and feedback sessions.

Adhere to policies: specific rules like "no smoking" areas or "pedestrian walkways" are not suggestions; they are conditions of employment.

Support the system: If a new safety software or reporting tool is introduced, learn it and use it rather than resisting the change.

4. Do Not Interfere with Safety Equipment

I have seen workers tape over limit switches or remove guards to "speed things up." This is often a criminal offense. You must never intentionally misuse or damage anything provided in the interests of health and safety.

Respect safeguards: Never bypass machine guarding, interlocks, or emergency stop buttons.

Maintain integrity: Do not deface safety signage, remove fire extinguishers from their posts, or discharge them unnecessarily.

Report damage: If you accidentally damage safety equipment, report it immediately so it can be fixed; do not hide it.

Pro Tip: In many jurisdictions, intentionally tampering with safety devices allows for immediate dismissal and can even lead to personal prosecution if someone is injured as a result.

Operational & Site Safety

Once you are out in the field—whether it's a warehouse floor or an offshore rig—your responsibilities shift to the practical execution of work.

5. Wear Personal Protective Equipment (PPE) Correctly

PPE is your last line of defense. It is not enough to just "have" it; you must wear it as trained and intended.

Check condition: Inspect your helmet, harness, or respirator before every shift for cracks, tears, or expiration dates.

Wear it properly: A chinstrap unbuckled or safety glasses on your forehead offer zero protection.

Store it right: Keep your PPE clean and stored in a designated area to prevent degradation from sunlight or chemicals.

6. Follow Safe Work Procedures (SWP)

Every high-risk task has a method statement or standard operating procedure. Your job is to adhere to this script without improvisation.

Read before working: Review the specific procedure for the task at hand, even if you have done it a hundred times.

Follow the sequence: Do not skip steps (e.g., purging a line before opening it) just because they seem tedious.

Use the right tools: Only use the tools specified in the procedure; improvising with the wrong tool is a leading cause of hand injuries.

7. Participate in Risk Assessments

You know the job better than the safety manager sitting in the office. Your input into Job Safety Analysis (JSA) or Risk Assessment is vital.

Identify hazards: Speak up about specific risks you face that might not be obvious on paper (e.g., a valve that is hard to reach).

Review controls: Verify if the proposed safety measures (like ventilation or barriers) are actually practical for the task.

Sign off: By signing a JSA, you are agreeing that you understand the risks; do not sign blindly.

8. Report Hazards Immediately

Walking past a hazard is the same as approving it. If you see something unsafe, you own it until it is reported or resolved.

Report minor issues: Even a small oil leak or a loose handrail needs to be logged.

Use the system: Utilize the company’s hazard reporting card or app to ensure there is a record of the issue.

Warn others: If you cannot fix it immediately, put up a temporary barrier or warning sign to alert colleagues.

9. Exercise Stop Work Authority

If conditions change or a task feels unsafe, you have the responsibility to stop working. I have never penalized a worker for stopping a job they thought was dangerous; I have only thanked them.

Trust your gut: If something feels wrong or different than the plan, pause the work.

Intervene for others: If you see a coworker doing something unsafe, stop them respectfully but firmly.

Wait for resolution: Do not resume work until the safety concern has been investigated and addressed by a supervisor.

Equipment & Competency

Machinery and lack of knowledge are two of the biggest killers in industry. Your responsibility is to manage both effectively.

10. Only Operate Equipment You Are Trained For

Just because you can drive a forklift doesn't mean you are authorized to do so. Competency requires verification.

Verify certification: Ensure your tickets and licenses (e.g., for cranes, forklifts, welding) are valid and on your person.

Refuse uncertified work: If a supervisor asks you to operate a machine you aren't trained on, you must refuse.

Know the machine: Be familiar with the specific model you are using, as controls can vary between manufacturers.

11. Inspect Tools and Machinery Pre-Use

The employer provides the tools, but you must ensure they are safe to use at that specific moment.

Conduct pre-starts: Run through the daily checklist for vehicles or heavy machinery (tires, hydraulics, lights).

Check power tools: Look for frayed cords, cracked casings, or missing guards on grinders and drills.

Tag out defectives: If a tool fails inspection, apply a "Do Not Operate" tag immediately and remove it from service.

12. Attend Required Safety Training

Training is not a break from work; it is work. You are responsible for absorbing and applying the knowledge provided.

Show up: Attend all scheduled inductions, refreshers, and specialized training sessions.

Pay attention: actively listen and ask questions if you do not understand a concept or rule.

Apply the learning: Transfer the theory from the classroom to the field immediately.

13. Maintain Housekeeping Standards

Poor housekeeping is the root cause of the vast majority of slips, trips, and fires. A clean site is a safe site.

Clean as you go: Do not wait until the end of the shift; clear waste and scraps as they are generated.

Keep paths clear: Ensure emergency exits, walkways, and electrical panels are never blocked by materials.

Manage spills: Clean up liquid spills immediately or deploy spill kits to prevent environmental contamination and slipping hazards.

Emergency & Health Management

When things go wrong, your reaction time and adherence to protocol determine the severity of the outcome.

14. Understand Emergency Procedures

When the alarm sounds, panic kills. You must know exactly what to do without waiting for instructions.

Know your exits: Always be aware of the nearest two emergency exits and the assembly point.

Memorize codes: Understand the difference between a fire alarm, a gas release alarm, and a man-down alarm.

Know your role: If you have a specific duty during an emergency (e.g., floor warden), know it inside out.

15. Report All Incidents and Near Misses

Data saves lives. We cannot fix hidden problems.

Report immediately: Do not wait until the end of the week; report injuries or incidents as soon as they happen.

Be honest: Describe exactly what happened, even if you made a mistake. The goal is learning, not blaming.

Include near misses: Report the "close calls"—these are free lessons that help us prevent future accidents.

16. Manage Fatigue and Health

You must be fit for work. This includes managing factors outside of work that affect your performance on site.

Get rest: Ensure you are getting adequate sleep before your shift, especially if working nights or long rosters.

Hydrate: In hot environments, drink water proactively, not just when you are thirsty.

Report illness: If you are taking medication that causes drowsiness or are feeling unwell, notify your supervisor.

17. Handle Hazardous Substances Safely

Chemicals are silent threats. You must respect the Safety Data Sheets (SDS).

Read the label: Never use a bottle or container that is unlabeled or has a faded label.

Use controls: Utilize fume hoods, gloves, and ventilation as specified in the COSHH or HazCom assessment.

Wash up: Practice good hygiene by washing hands thoroughly before eating or smoking to prevent ingestion of toxins.

Culture & Behavior

Finally, safety is about mindset and influence.

18. Avoid Horseplay and Pranks

Industrial environments are not playgrounds. Distractions and physical pranks can lead to severe injuries near heavy machinery.

Stay professional: Maintain a focus on the task and avoid practical jokes that could startle or distract coworkers.

Respect boundaries: Do not mess with someone's PPE or tools as a "joke."

Discourage others: If you see horseplay, do not encourage it; step in to stop it.

19. Lead by Example

You do not need "Manager" in your title to be a leader. Junior workers watch the experienced hands.

Model compliance: If the veteran worker wears their safety glasses, the apprentice will too.

Mentor new hires: Help new employees navigate the safety culture and correct them gently if they drift.

Stay positive: Avoid cynical talk about safety rules; a negative attitude spreads faster than a virus.

20. Suggest Improvements

You are the expert in your specific task. If you see a better, safer way to do something, share it.

Submit ideas: Use suggestion boxes or safety committee meetings to propose new tools or methods.

Feedback on gear: Tell management if the current PPE is uncomfortable or ineffective so they can buy better options.

Innovate: Look for opportunities to eliminate hazards entirely (e.g., using a drone for inspection instead of climbing).

Summary of Responsibilities

Category | Key Employee Responsibility |

Legal | Take reasonable care of self and others; Cooperate with employer. |

Operational | Follow procedures; Wear PPE; Report hazards. |

Equipment | Inspect tools; Operate only if trained; Do not tamper with guards. |

Emergency | Know evacuation routes; Report all incidents/near misses. |

Behavioral | Stop unsafe work; Avoid horseplay; Lead by example. |

Conclusion

Safety is not something that is done to you; it is something that is done by you. Throughout my career, the most safe and productive sites I have managed were not the ones with the most expensive paperwork, but the ones where every single employee, from the janitor to the crane operator, took personal ownership of these 20 responsibilities.

When you walk through the gate tomorrow, remember that your family is expecting you to return. The regulations and rules I have outlined here are the roadmap to making that happen. Do not wait for a safety officer to tell you to put your helmet on or to clean up a spill. Take charge of your own safety, look out for your mates, and ensure that we all finish the shift as healthy as we started it.

Comments

Loading...