I vividly recall a tense silence falling over a boardroom in a heavy manufacturing complex after I presented the findings of a serious near-miss investigation. One of the non-executive directors leaned forward, looking genuinely rattled, and asked the question that shifts the atmosphere in every executive meeting: "If this had been a fatality, would I be sitting in a courtroom right now?" In that moment, the conversation moved from abstract statistics to personal liability. It wasn't about whether the workers had wearing hard hats; it was about whether the board had exercised due diligence to prevent the failure of the management system.

The reality of modern safety governance is that you can delegate the task, but you cannot delegate the accountability. As an HSE Director who has guided boards through ISO 45001 certifications and crisis management, I have seen that the most effective organizations are those where health and safety is treated as a core business risk, not a technical sidecar. This article outlines the ten critical responsibilities every director must personally own to ensure legal compliance, operational continuity, and, most importantly, the preservation of life.

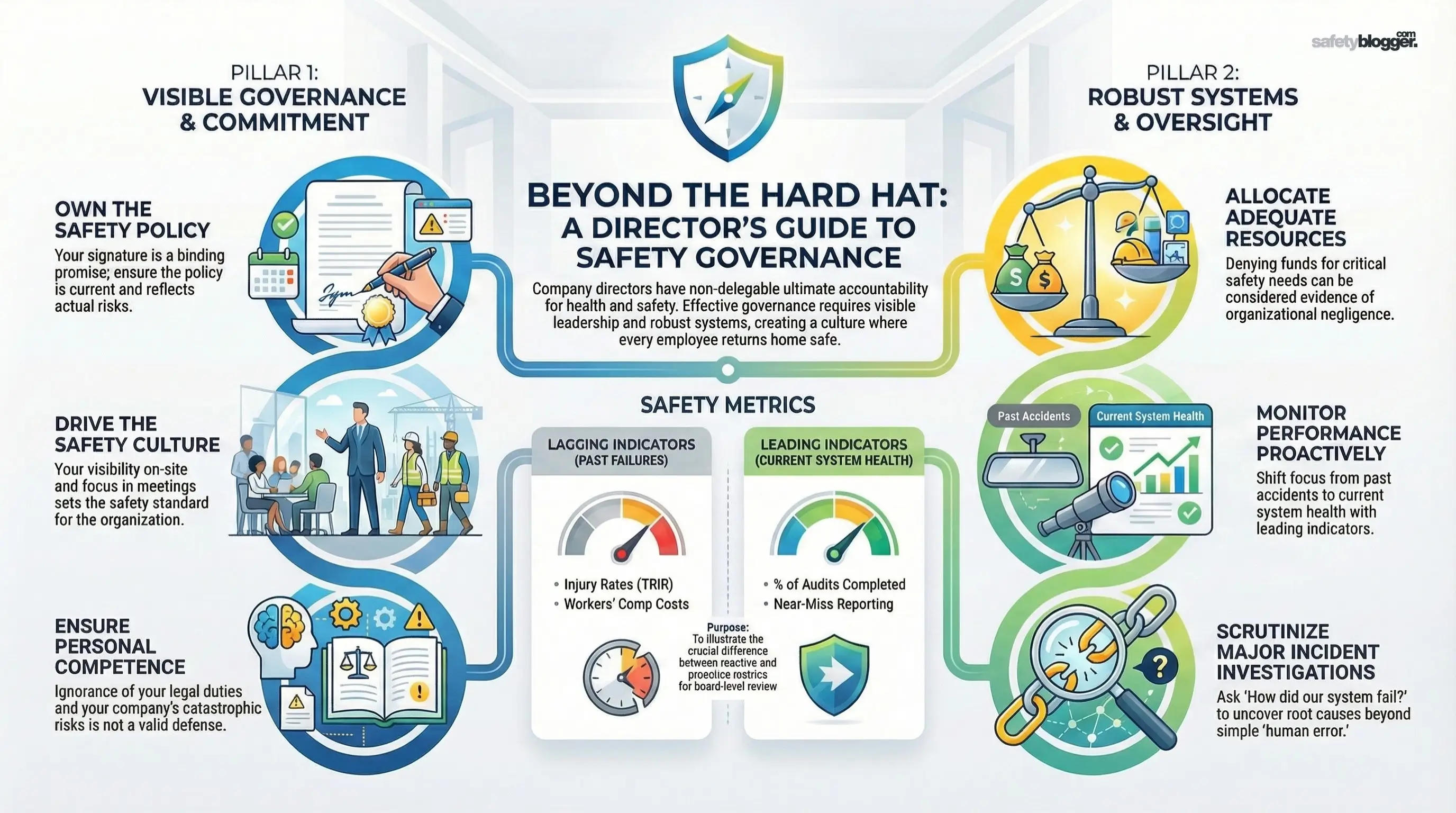

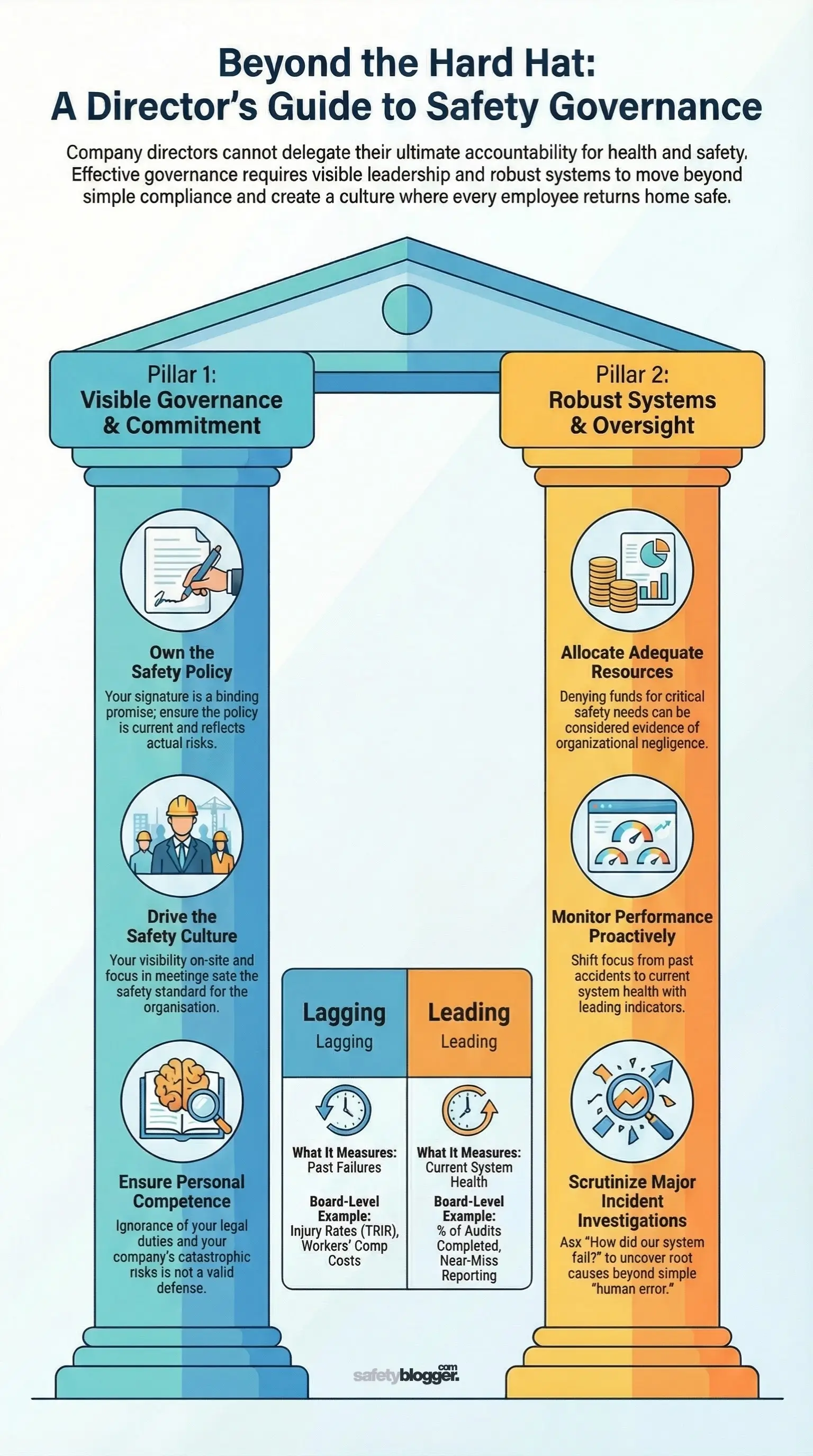

1. Ownership of the Health and Safety Policy

A safety policy is often treated as a piece of paper to be signed and filed, but for a director, it is a binding declaration of intent. I have audited facilities where the policy was signed by a CEO who had left the company three years prior—a clear signal to any regulator that safety is not a priority.

Directors must ensure the Health and Safety Policy is not only current but reflects the organization's actual risk profile.

Approve and Sign: The most senior executive must sign the policy to demonstrate top-level commitment.

Define Objectives: The policy must set clear, measurable targets (e.g., "Zero Harm" or specific reduction in TRIR).

Review Regularly: It must be reviewed annually or after significant organizational changes to remain relevant.

Pro Tip: When I audit a company, I ask random employees if they know what the safety policy says. If they don't, the Director has failed to communicate the vision.

2. Ensuring Adequate Resourcing

One of the most common root causes I uncover during accident investigations is a lack of resources—not just money, but time and personnel. Directors are responsible for allocating the necessary budget to implement the safety management system effectively.

If a safety manager requests budget for critical machine guarding and is denied due to "cost-cutting," and an amputation occurs, the paper trail of that denial becomes evidence of negligence.

Financial Budget: Allocating funds for PPE, training, maintenance, and emergency equipment.

Human Capital: Ensuring there are enough competent staff to do the work safely without rushing.

Specialized Advice: Budgeting for external expertise (e.g., industrial hygienists or structural engineers) when internal competence is insufficient.

3. Driving Safety Culture and Visibility

Culture flows from the top down. I often tell boards, "The shadow of the leader determines the behavior of the pack." If directors only talk about production targets and profit margins, site managers will cut corners to please them.

Directors must provide "Visible Felt Leadership." This means being seen on the shop floor, not just in the boardroom.

Site Tours: regularly visiting high-risk areas wearing full PPE.

Safety Moments: Starting every board meeting with a safety topic or incident review.

Behavioral Modeling: Strictly adhering to safety rules themselves (e.g., holding handrails, wearing eye protection).

4. Competence and Training

Many directors mistakenly believe that because they are not "technical," they don't need safety training. However, under regulations like the UK's Health and Safety at Work Act or similar global standards, ignorance is not a defense.

Directors need to understand their legal duties and the specific hazards of their industry.

Director-Specific Training: Courses like IOSH Leading Safely or similar executive programs.

Legal Updates: Keeping abreast of changes in legislation (e.g., new exposure limits or manslaughter laws).

Risk Understanding: Knowing the top 5 catastrophic risks of the business (e.g., explosion, structural collapse, toxic release).

5. Integrating Risk Management

Safety risks must be treated with the same rigor as financial or reputational risks. In my experience, boards that silo HSE into a separate department often fail to see the systemic threats facing their operation.

Directors must ensure that risk assessments are not just operational tasks but are integrated into business decisions.

Enterprise Risk Management: Including major HSE risks in the corporate risk register.

Change Management: Evaluating the safety impact of mergers, acquisitions, or restructuring before they happen.

Procurement: Ensuring safety criteria are weighted in tender processes for contractors and suppliers.

6. Monitoring Performance (Beyond Lagging Indicators)

I have sat in too many board meetings where directors high-five over a "Zero LTI" (Lost Time Injury) month, unaware that serious near-misses are spiking. Relying solely on injury rates is like driving a car looking only at the rearview mirror.

Directors must demand and scrutinize a mix of data.

Indicator Type | What It Tells You | Examples for Board Review |

Lagging | What went wrong in the past. | Injury rates (TRIR), Workers' Comp costs, Fines. |

Leading | Current health of the system. | % of audits completed, Training compliance, Near-miss reporting frequency. |

Culture | Workforce sentiment. | Safety climate survey scores, Participation in safety committees. |

7. Supply Chain and Contractor Oversight

In global EPC projects or large-scale manufacturing, a significant percentage of incidents involve contractors. Directors cannot wash their hands of this liability. If a subcontractor dies on your site due to your unsafe environment or lack of oversight, you are responsible.

Prequalification: Mandating that only safety-accredited contractors are hired.

Bridging Documents: Ensuring clear interface management between client and contractor safety systems.

Performance Review: firing contractors who habitually violate safety standards, regardless of their price.

8. Incident Investigation and Review

When a major incident or high-potential near-miss occurs, the Director's role is not to blame the worker, but to ask, “How did our system fail him?”

I always advise directors to personally review the investigation reports for any incident with potential for fatality or permanent disability.

Root Cause Analysis: Ensuring investigations go beyond "human error" to find systemic failures.

Corrective Actions: Tracking the closure of action items to prevent recurrence.

Legal Privilege: Understanding how to manage investigations in anticipation of litigation.

9. Legal Compliance and Due Diligence

Compliance is the baseline, not the ceiling. However, falling below that baseline is a criminal offense in many jurisdictions. Directors must ensure a mechanism exists to identify and adhere to all applicable laws (OSHA, local labor laws, environmental regulations).

Legal Register: Ensuring the company maintains an up-to-date register of legal obligations.

Audit Programs: Commissioning internal and external audits (ISO 45001) to verify compliance.

Whistleblowing: Establishing a channel for employees to report non-compliance without fear of retaliation.

10. Workforce Engagement

Finally, ISO 45001 places heavy emphasis on "Consultation and Participation of Workers." Directors must ensure that the voice of the workforce reaches the boardroom.

I have seen safety committees that are merely rubber-stamping exercises. A director's responsibility is to ensure these forums are active and that workers feel empowered to stop unsafe work.

Union/Rep Engagement: actively meeting with safety representatives.

Stop Work Authority: publicly supporting any employee who stops a job they deem unsafe.

Feedback Loops: ensuring that when workers raise a concern, they receive a response on what was done about it.

Conclusion

The role of a Director in health and safety is not to be a safety expert, but to be a safety leader. It is about governance, resource allocation, and setting the moral compass of the organization.

When I look back at the most successful companies I have worked with—from mining giants to renewable energy startups—the common denominator was a board that viewed safety not as a cost, but as a core value. Your signature on the policy is a promise to the families of your workforce that you have done everything reasonably practicable to send their loved ones home safe.

Comments

Loading...