I once stood on a $500 million petrochemical expansion project where a sub-contractor’s welder decided to bypass the hot work permit system because "it was just a quick tack weld." He didn't check the other side of the bulkhead, where another contractor was applying flammable solvent-based coating. The resulting flash fire was small, but it shut down the site for three days and nearly cost two men their eyesight. It wasn’t just a failure of the welder; it was a catastrophic breakdown in the coordination, oversight, and definition of responsibilities between the client, the main contractor, and the sub-contractor.

This article isn't about blaming the "little guy"; it is about defining exactly who owns the risk when multiple companies share one fence line. Whether you are a Project Manager hiring a specialized crew or a Contractor trying to navigate a client’s complex safety management system (SMS), ambiguity is your enemy. Below, I break down the specific legal, operational, and moral health and safety responsibilities of contractors, moving beyond the paperwork to what actually keeps people alive in the field.

1. The "Not My Problem" Myth: Legal & Regulatory Reality

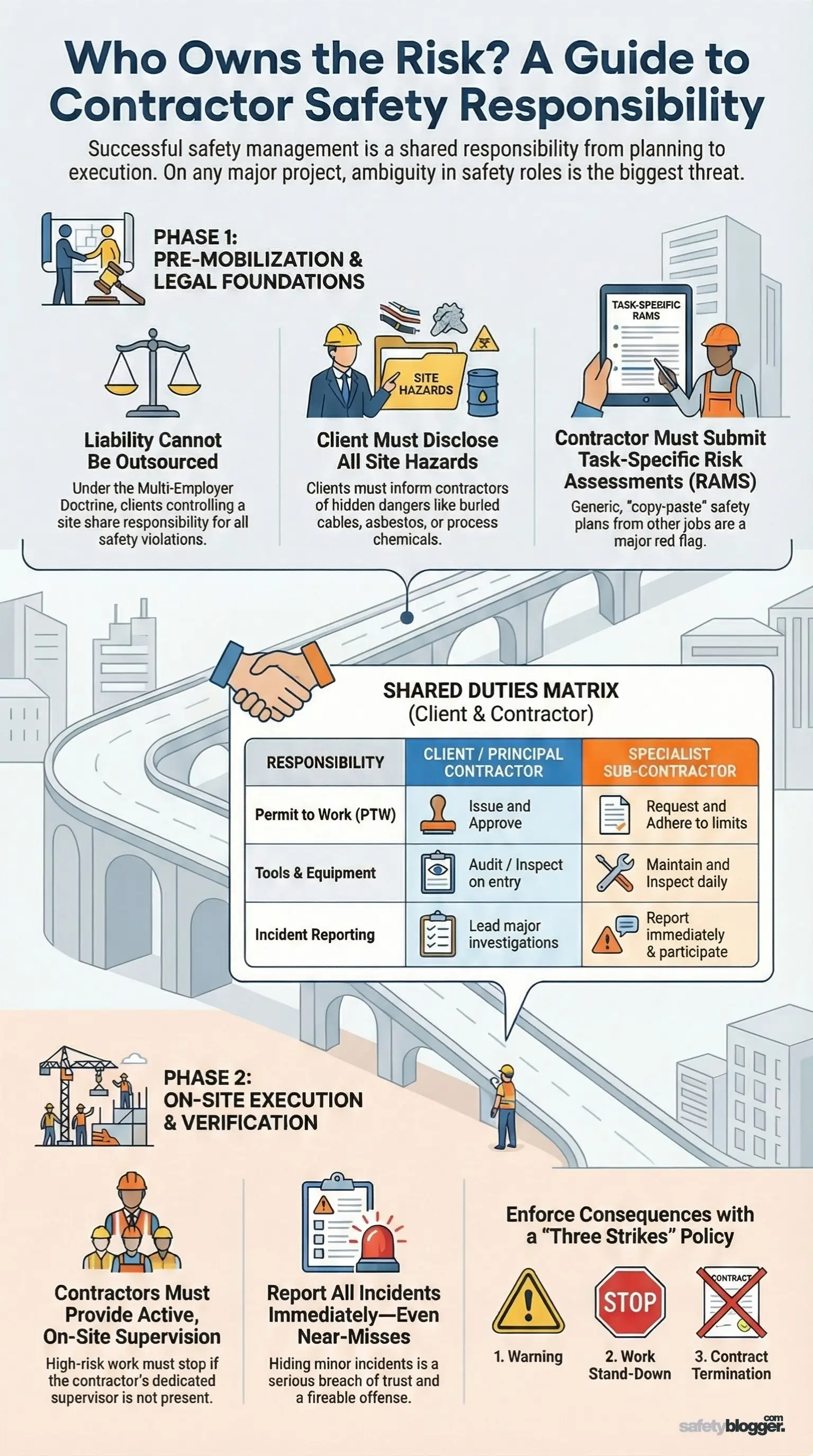

Many clients believe that by hiring a contractor, they are outsourcing the risk. This is false. In my experience auditing ISO 45001 sites and dealing with regulatory bodies like OSHA, I have seen "controlling employers" cited alongside "exposing employers" repeatedly. You cannot contract away your liability.

The Multi-Employer Doctrine (OSHA): If you control the site, you own a share of the safety violations found there, even if your own employees weren't the ones exposed.

ISO 45001 Clause 8.1.4.2: This standard explicitly requires the host organization to coordinate procurement with contractors. You must identify hazards before they mobilize.

Duty of Care: Contractors have an absolute duty to ensure their work does not endanger themselves, the client’s staff, or the public.

Pro Tip: Never accept a contract that vaguely says "Contractor will follow all safety rules." That is a trap. The contract must specify whose safety rules apply—the Client’s or the Contractor’s. If it’s the Client’s, you better know them inside out before you bid.

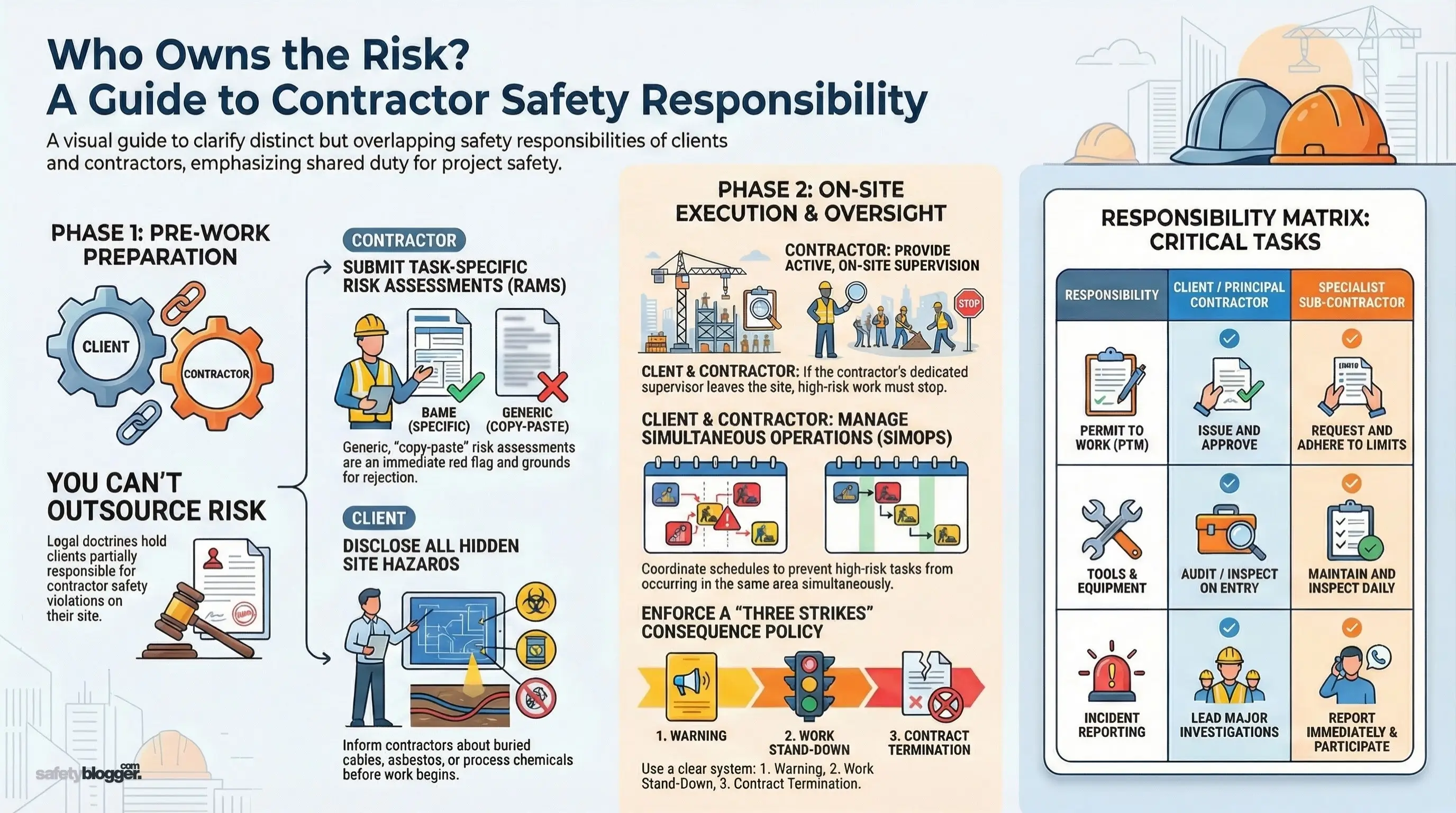

2. Pre-Mobilization: The Gatekeeper Phase

The most dangerous phase of any project is the week before boots hit the ground. If a contractor mobilizes without a clear plan, accidents are guaranteed. As a Construction HSE Manager, I refuse to issue an access badge until the following responsibilities are met.

Contractor Responsibilities:

Risk Assessments & Method Statements (RAMS): Submit task-specific RAMS. Generic "copy-paste" risk assessments from previous jobs are immediate grounds for rejection.

Competency Verification: Prove that the crane operator is actually certified for this tonnage, not just general lifting.

Equipment Certification: All plant and machinery (excavators, welding sets, generators) must have valid third-party inspection tags before entering the gate.

Client/Principal Contractor Responsibilities:

Hazard Disclosure: You must tell the contractor about hidden site hazards (e.g., buried cables, asbestos, lead paint, or process chemicals). Hiding this info to "keep the bid low" is criminal.

Bridging Documents: For complex projects, create a document that bridges the Client’s Safety Management System with the Contractor’s. It answers the question: "In an emergency, whose alarm do we follow?"

3. On-Site Execution: The Operational Reality

Once work begins, the theoretical plan meets the muddy reality of the site. The contractor’s primary responsibility here is compliance and supervision. I often see contractors sending a crew of ten with no supervisor, expecting the Client’s safety officer to babysit them. This is unacceptable.

The Contractor Must Provide:

Active Supervision: A dedicated supervisor or foreman must be present. If the supervisor leaves the site, high-risk work stops.

Toolbox Talks (TBT): Daily briefings relevant to that day's specific hazards, not just reading a safety poster.

Incident Reporting: A contractual obligation to report all incidents, including near-misses, immediately. "We fixed it, so we didn't tell you" is a firing offense on my sites.

Managing SIMOPS (Simultaneous Operations):

When a scaffolding contractor is working above a piping contractor, who is responsible for dropped objects? Both.

The Scaffolder must secure tools and use toe boards.

The Piper must respect barricades and not work in the line of fire.

The Principal Contractor must schedule the work so they aren't stacking risks on top of each other.

4. Audit, Inspection, and Consequence Management

Trust is good; checking is better. A contractor might have a perfect safety manual, but if their field crew is using damaged slings or bypassing guards, the manual is worthless.

The Audit Cycle:

Tier 1: Contractor does their own internal inspections (daily/weekly).

Tier 2: Client HSE conducts walkthroughs and spot checks (weekly).

Tier 3: External Third-Party Audits (annually or per project phase).

If a contractor consistently violates safety rules, the "Three Strikes" policy is standard in the industry:

Verbal/Written Warning: For minor infractions (e.g., missed PPE).

Stand-Down: Work stops, the crew is retrained at their own cost.

Termination: The contract is voided, and the contractor is blacklisted.

Quick Reference: Division of Duties

Responsibility | Client / Principal Contractor | Specialist Sub-Contractor |

Site Induction | Provide (General site rules, emergency exits) | Attend & Verify understanding |

PPE | Set minimum standards (e.g., "All Orange Vests") | Supply compliant gear to own staff |

Permit to Work (PTW) | Issue and Approve | Request and Adhere to limits |

Tools & Equipment | Audit / Inspect on entry | Maintain and Inspect daily |

Incidents | Lead major investigations | Report immediately & participate |

Training | Verify competency (check cards) | Ensure workers are trained |

Conclusion

In ten years of high-risk projects, I have learned that the safest contractors are not the ones with the thickest manuals, but the ones who treat safety as a personal value rather than a contractual hurdle. The piece of paper says the contractor is responsible for their own safety, but the moral reality is that we are our brother's keeper.

If you are a contractor, do not cut corners to save a few minutes; you are risking your livelihood and your workers' lives. If you are a client, do not squeeze the contractor's budget so tight that they can't afford to work safely. True safety is a partnership, and it starts with accepting responsibility before the first tool is lifted.

Comments

Loading...